Production Facility

Technopack’s production facility is industry leading with state-of-the-art design, engineering, and technologies delivered by the best names in the packaging business. The plant runs a 2.8 meter triple knife corrugating line from BHS Germany with an annual capacity of 90,000 tons of corrugated products. The line is equipped with a complete waste handling and baling system. Converting is carried out using the latest technologies of Bobst and Goepfert machines with a sophisticated materials handling system that is fully automated.

The entire plant has been designed according to the latest international standards and technologies in an integrated box plant to deliver scalable production capacities, world class quality, and maximum efficiencies.

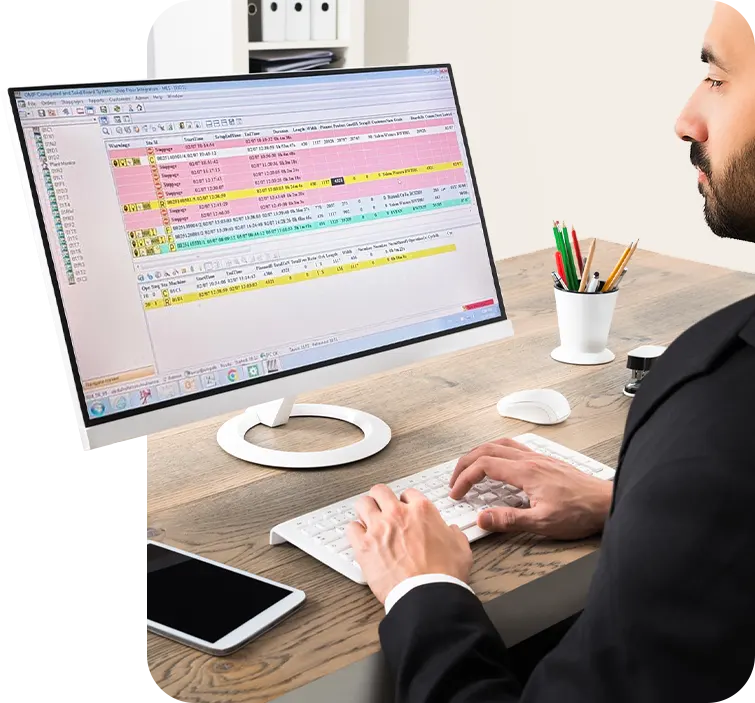

We have a passion for excellence. The business infrastructure we have built throughout the years drives Technopack’s performance across all business functions. Ranging from automated production scheduling, enterprise resource planning, rigorous quality management, and continuous improvement systems and processes. We focus on enhancing productivity, increasing efficiency, reducing waste, and ensuring our operational processes stay lean.

Technopack today is positioned locally and in the region to be the leading partner for corrugated packaging needs with a strong platform for sustainable growth, value creation, and staying ahead.

Production Facility

Technopack’s production facility is industry leading with state-of-the-art design, engineering, and technologies delivered by the best names in the packaging business. The plant runs a 2.8 meter triple knife corrugating line from BHS Germany with an annual capacity of 90,000 tons of corrugated products. The line is equipped with a complete waste handling and baling system. Converting is carried out using the latest technologies of Bobst and Goepfert machines with a sophisticated materials handling system that is fully automated.

The entire plant has been designed according to the latest international standards and technologies in an integrated box plant to deliver scalable production capacities, world class quality, and maximum efficiencies. We have a passion for excellence.

The business infrastructure we have built throughout the years drives Technopack’s performance across all business functions.

Ranging from automated production scheduling, enterprise resource planning, rigorous quality management, and continuous improvement systems and processes. We focus on enhancing productivity, increasing efficiency, reducing waste,

Technopack today is positioned locally and in the region to be the leading partner for corrugated packaging needs with a strong platform for sustainable growth, value creation, and staying ahead.

Production Facility

Order Management

Storage Facilities

Package Design

Storage

Facilities

The extensive storage facilities we have for raw materials and for finished goods, allow Technopack to adapt to changing market needs with flexibility and speed. Our customers can rely on us to promptly provide them with the quantity they need, when they need it.

Order

Management

The sophisticated systems and machine integration we have allow us to track all jobs throughout the entire process, incorporating real time reporting of job status and enabling control and collection of accurate and concise manufacturing, storage, and delivery details.

Our professional account executives are in constant contact with customers to proactively provide on-time feedback on order fulfillment activities.

Package Design

We closely work with our customers to build and design packaging solutions that fits their needs. Defining the project starts with analyzing the packaging product, its needs, usage, manufacturing and distribution requirements, marketing considerations, timing, and cost constraints.

Our in-house capabilities and the extensive experience of our design team, enables us to create fast prototypes using the most advanced techniques and tools in structural and graphic design. Prototypes can be printed digitally or in full size print samples, giving our customers the opportunity to see. an accurate visual representation of their packaging requirements.

As needed, corrugated boxes undergo strict, structural performance tests at the Technopack QA Lab, using compression tests and safety margins for the stacking strength based on the consumer product’s storage needs.